Imt, Faridabad, Haryana

- GST NO. : 06AEHPA2177B1Z4

View Mobile Number

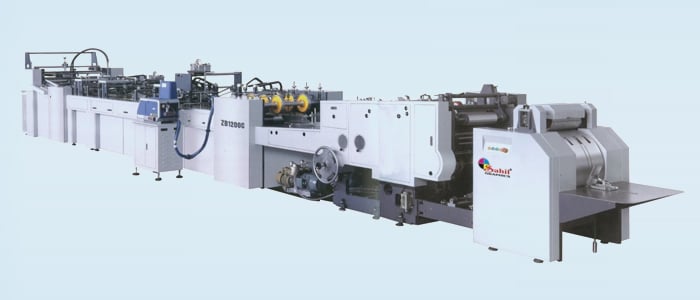

Paper Bag Making Machine

Leading Manufacturers, Exporters, Wholesaler and Importer of Fully Automatic Paper Bag Making Machine with Inline Handle, Roll Fed Square Bottom Paper Bag Making Machine, Square Bottom Paper Bag Making Machine with Two Color Inline Printing, Sharp Bottom Paper Bag Machine, V- Bottom Paper Bag Making Machine, V- Bottom Paper Bag Making with Two Color Printing Machine, V- Bottom Paper Bag Making with Four Color Printing Machine, Grocer Paper Bag Making Machine with Servo Motor, Grocery Paper Bag Making with Four Color Printing Machine & Servo Motor and Fully Automatic Sheet Feeding Paper Bag Making Machine from Faridabad.

| Business Type | Manufacturer, Exporter, Supplier, Importer |

| Brand Name | Sahil |

| Total power | 25kw (3phase) |

| Country of Origin | India |

| Maximum Speed | 90bag/min |

| Machine Dimension | 15000x3000x2500mm (lxwxh) |

| Paper Bag Width | 200-420MM |

| Bag Bottom Width | 80-150mm |

| Bag width | 220-460mm |

| Bag width With Handle | 240-460mm |

| Paper Thickness | 60-150GSM |

| Max. Bag Bottom Width | 80-200mm |

| Max. Bag Bottom Width with Handle | 100-180mm |

| Tube Length with Handle | 260-470mm |

| Tube Length Without Handle | 260-530mm |

| Rolled Paper Width | 625-1350mm |

| Rolled Paper Diameter | 1300mm |

| Inner Diameter of Paper | 76mm |

| Air Pressure | 690kpa |

| Net Weight | 12000kg |

| Max. Speed | 30-180pcs/min |

| Dimension Approx. | 15*8*2.6m |

The Square bottom paper bag machine design embodies what Sahil Graphics stands for and features great deal of innovation haven’t seen before. This New Gen of square bottom paper bag making expresses-

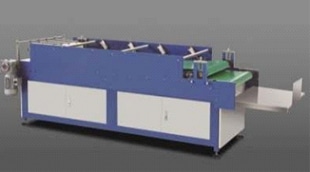

| Business Type | Manufacturer, Exporter, Supplier, Importer |

| Brand Name | Sahil |

| Bag Width | 140-360mm |

| Paper Thickness | 60-150gsm |

| Max. Bag Bottom Width | 80-200mm |

| Tube Length | 270-530mm |

| Rolled Paper Width | 480-1050mm |

| Rolled Paper Diameter | 1200mm |

| Inner Diameter of Paper | 76mm |

| Total Power | 15kw (3phase) |

| Air Pressure | 690kpa |

| Net Weight | 8500kg |

| Max. Speed | 30-200pcs/min |

| Machine Size | 10000*3700*2200 |

The Square bottom paper bag machine design embodies what Sahil Graphics stands for, and features great deal of innovation haven’t seen before. This New Gen of square bottom paper bag making express:

- Widest bag size range.

- Durability.

- Performance.

- Ease of Operations.

- Automation to Reduce wastage.

| Business Type | Manufacturer, Exporter, Supplier, Importer |

| Brand Name | Sahil |

| Bag Width | 140-360mm |

| Paper Thickness | 60-150gsm |

| Max. Bag Bottom Width | 80-200mm |

| Tube Length | 270-530mm |

| Rolled Paper Width | 480-1050mm |

| Rolled Paper Diameter | 1200mm |

| Inner Diameter of Paper | 76mm |

| Total Power | 15kw (3phase) |

| Air Pressure | 690kpa |

| Net Weight | 8500kg |

| Max. Speed | 30-200pcs/min |

| Machine Size | 10000*3700*2200 |

The Square bottom paper bag machine design embodies what Sahil Graphics stands for, and features great deal of innovation haven’t seen before. This New Gen of square bottom paper bag making express:

- Widest bag size range.

- Durability.

- Performance.

- Ease of Operations.

- Automation to Reduce wastage.

| Business Type | Manufacturer, Exporter, Supplier, Importer |

| Brand Name | Sahil |

| Model | Sharp-260 |

| Length of Cutting Bag | 100-450mm |

| Bag Width | 65-250mm |

| Gusset | 20-120mm |

| Bag Mouth Height | 15/20mm |

| Bag Speed | 50-600pcs/min |

| Paper Feed Width | 260-740mm |

| Paper Material Diameter | 200-1000mm |

| Paper Material Thickness | 35-80g/m² |

| working Air Current | More Than 0.12m3/minutes, 0.6-1.2 Mpa |

| Electric Power | 380v3 Phase 4 Wire 13kw |

| Total Weight | 4500kg |

| Machine Dimension | 5900x2200x1600mm |

SHARP-260 Full automatic high speed paper bag making machine use primary color rolling paper or printed rolling paper such as Kraft paper, striped brown paper, slick paper, food coated paper, medico paper and SO on, bag making processconsist of puncture, side gluing, side folding, bag forming, cut off, bottom folding, bottom gluing, finish product delivered in onetime. Our machine have advantage of easy operation, high efficiency, more steady, it is an ideal machine for make different kind of paper bag, snack food paper bag, bread paper bag, dry fruit paper bag and environment friendly paper bag.

| Business Type | Manufacturer, Exporter, Supplier, Importer |

| Brand Name | Sahil |

| Paper Weight | 30-80gsm |

| Bag Length | 160-450mm |

| bag Width | 70-350mm |

| the Width of Paper Roll | 260-900mm |

| unwind Roll Dia | 900mm |

| machine Speed | 60-600pcs/min |

| drive Motor | 3.7 Kw Ac Variable |

| glue Motor | 70 W |

| machine Power | 4kw |

| machine Weight (approx.) | 2500kg |

| Delivery Time | Ready Stock |

| Packaging Details | Shrink wrap |

A revolution machine V LINE -350 which is mastered to produce finest paper bag with high performance speed. Get the bags ready at minimum making cost. Great finishing equipped by servo motor and glue motor. Rugged structure ensures batter quality and life of machine. The bag length is controlled by gear. Change length need change gear. The parameter is controlled by inverter motor.

| Business Type | Manufacturer, Exporter, Supplier, Importer |

| Brand Name | Sahil |

| paper Weight | 30-80gsm |

| Bag Length | 160-450mm |

| bag Width | 70-350mm |

| the Width of Paper Roll | 260-900mm |

| unwind Roll Dia | 1000 Mm |

| drive | 3.7kw Ac Variable |

| Glue Motor | 70 W |

| Printing Type | Flexo |

| Print Repeat Range | 280-450 |

| max. Effective Printing Width | 900 |

| flexo Plate Thickness | 1.7 Mm |

| machine Speed | 60-600pcs/min |

| machine Power | 4kw |

| Machine Weight | 3300kg |

A revolution machine V LINE-350C which is mastered to produce finest paper bag with high performance speed. Get the bags ready at minimum making cost. Great finishing equipped by servo motor and glue motor. Rugged structure ensures batter quality and life of machine. The bag length is controlled by gear. Change length need change gear. The parameter is controlled by inverter motor.

| Business Type | Manufacturer, Exporter, Supplier, Importer |

| Brand Name | Sahil |

| Country of Origin | India |

| paper Weight | 30-80gsm |

| Bag Length | 160-450mm |

| bag Width | 70-350mm |

| the Width of Paper Roll | 260-900mm |

| unwind Roll Dia | 1000 Mm |

| drive | 3.7kw Ac Variable |

| glue Motor | 70 W |

| printing Type | Flexo 4 Colour |

| print Repeat Range | 280-450 |

| max. Effective Printing Width | 900 |

| flexo Plate Thickness | 1.7 Mm |

| machine Speed | 60-500pcs/min |

| Machine Power | 4kw |

| Machine Weight | 4200kg |

A revolution machine V-LINE-350 4C which is mastered to produce finest paper bag with high performance speed. Get the bags ready at minimum making cost. Great finishing equipped by servo motor and glue motor. Rugged structure ensures batter quality and life of machine. The bag length is controlled by gear. Change length need change gear. The parameter is controlled by inverter motor.

| Business Type | Manufacturer, Exporter, Supplier, Importer |

| Brand Name | Sahil |

| paper Weight | 30-80gsm |

| bag Length | 160-450mm |

| bag Width | 70-350mm |

| the Width of Paper Roll | 260-900mm |

| unwind Roll Dia | 900mm |

| machine Speed | 60-400pcs/min |

| machine Power | 6 Kw |

| machine Weight (approx.) | 2500kg |

A revolution machine V LINE-350S which is mastered to produce finest paper bag with high performance speed. Get the bags ready at minimum making cost. Great finishing equipped by servo motor and glue motor. Rugged structure ensures batter quality and life of machine. The bag length is controlled by Servo Motor. The parameter is controlled by inverter motor.

| Business Type | Manufacturer, Exporter, Supplier, Importer |

| Brand Name | Sahil |

| paper Weight | 30-80gsm |

| bag Length | 160-450mm |

| bag Width | 70-350mm |

| the Width of Paper Roll | 260-900mm |

| unwind Roll Dia | 900mm |

| machine Speed | 60-400pcs/min |

| machine Power | 6 Kw |

| machine Weight (approx.) | 2500kg |

A revolution machine V-LINE-350 4C which is mastered to produce finest paper bag with high performance speed. Get the bags ready at minimum making cost. Great finishing equipped by servo motor and glue motor. Rugged structure ensures batter quality and life of machine. The bag length is controlled by Servo Motor. The parameter is controlled by inverter motor.

| Business Type | Manufacturer, Exporter, Supplier, Importer |

| Brand Name | Sahil |

| Input Max Size (sheet) | 1200x600mm |

| input Min Size (sheet) | 560x320mm |

| bottom Width | 80-175mm |

| bag Width | 180-430mm |

| Sheet Weight | 140-300g |

| speed | 50-80pcs/min |

| machine Dimensions | 15150 X 2400 X 1800 Mm |

| glue Type | Holt Melt + Water Base |

| machine Weight (approx.) | 12 T |

The sheet feeding SG1200C-430 paper bag producing machine is suitable for high volume paper bag production, using blank sheet or creased paper. Equipped with PLC control, frequency controlled speed adjustment as well as remote control. Automatic, non-stop feeding register, side gluing, gusset forming, bottom folding and pasting, automatic collection and counting – all in one uninterrupted work-flow. Optional with compaction and output unit. Standard with environmentally friendly water based cold glue system. Nordson hot-melt gluing unit for thicker paper as option available. Tube edge pasting alternatively on wide or small side. Capable to produce both, front- and back joint edge - providing a wide range of different bag types, whatever your customers’ needs or specific requirements. Stable operating at high speeds ensures high quality paper bags, finished on time